What are the key benefits and advantages of using PVC ventilation ducting fabric in industrial applications?

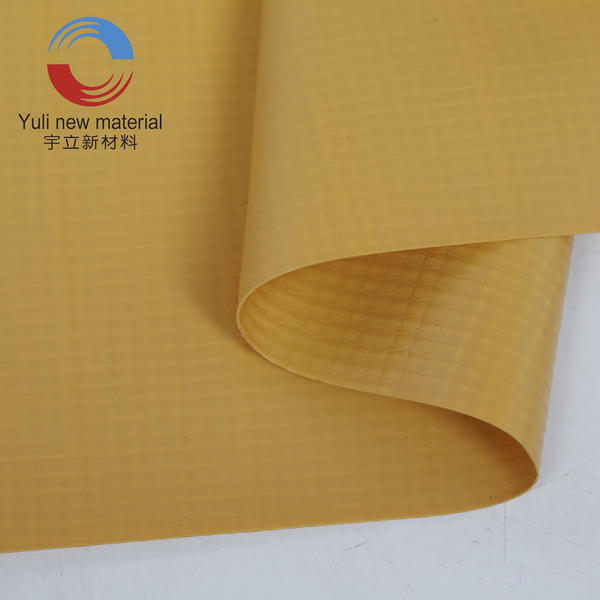

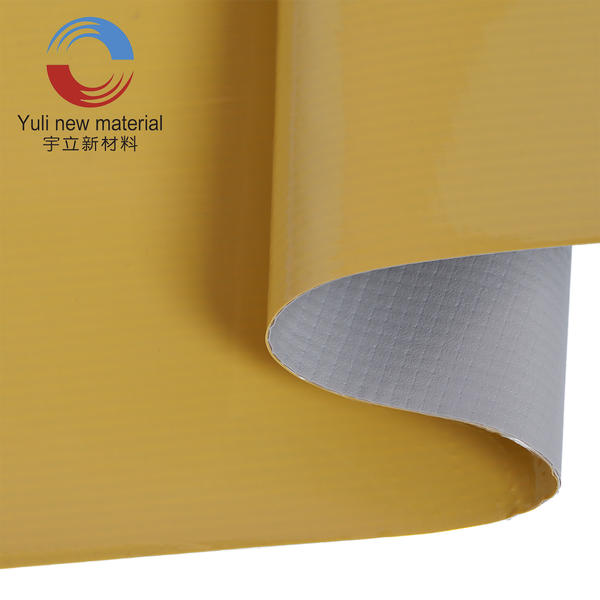

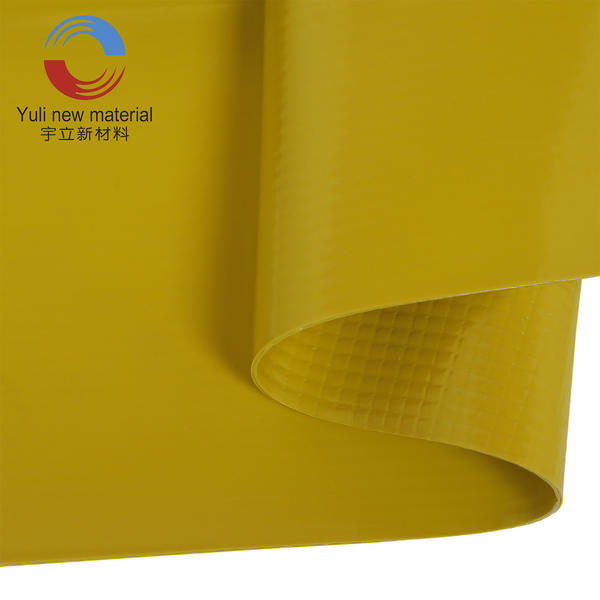

Flexibility and Versatility: One of the key benefits of PVC ventilation ducting fabric is its flexibility and versatility. PVC fabric can be easily bent, twisted, and maneuvered to fit into tight spaces or complex ducting configurations. This flexibility allows for easy installation, even in challenging industrial environments where space constraints may exist.

Lightweight: PVC fabric is lightweight compared to alternative materials such as metal or fiberglass. This characteristic makes it easier to handle and transport during installation or reconfiguration. The lightweight nature of PVC fabric also reduces the overall load on supporting structures, making it suitable for applications where weight considerations are crucial.

Excellent Chemical Resistance: PVC ventilation ducting fabric is highly resistant to a wide range of chemicals, acids, and alkalis. This resistance allows for its safe use in industries where chemical exposure is a concern, such as chemical processing plants or laboratories. PVC fabric's ability to withstand chemical interactions helps maintain the integrity and longevity of the ducting system.

Corrosion Resistance: PVC fabric is inherently resistant to corrosion, which makes it an ideal choice for industrial applications where moisture or aggressive environments are present. Unlike metal ducting, PVC fabric does not rust or deteriorate when exposed to moisture, making it suitable for applications in humid or damp conditions.

Energy Efficiency: PVC ventilation ducting fabric offers excellent insulation properties, helping to minimize heat loss or gain within the ducting system. The fabric's insulating characteristics contribute to energy efficiency by reducing the need for additional heating or cooling to compensate for temperature fluctuations. This energy-saving feature can lead to lower operational costs and a more sustainable industrial operation.

Cost-Effectiveness: PVC fabric is generally more cost-effective compared to alternative materials such as metal or fiberglass. The lower cost of PVC fabric, combined with its lightweight nature and ease of installation, can result in significant cost savings in terms of material procurement, transportation, and labor expenses. PVC fabric's durability and long service life further enhance its cost-effectiveness by minimizing the need for frequent replacements or repairs.

Low Maintenance: PVC ventilation ducting fabric requires minimal maintenance compared to other materials. The fabric is resistant to mold, mildew, and bacterial growth, which helps maintain good air quality within the ducting system. Additionally, PVC fabric can be easily cleaned with simple techniques such as wiping or vacuuming, ensuring optimal performance and prolonging its lifespan.

Fire Resistance: PVC ventilation ducting fabric is inherently fire-resistant. It has a high ignition temperature and low flame spread, making it suitable for applications where fire safety is a priority. PVC fabric can help contain the spread of fire within the ducting system, providing valuable time for evacuation and minimizing property damage.

In summary, PVC ventilation ducting fabric offers numerous benefits and advantages for industrial applications. Its flexibility, lightweight nature, chemical resistance, corrosion resistance, energy efficiency, cost-effectiveness, low maintenance requirements, and fire resistance make it a reliable choice for various industries where efficient and reliable ventilation is crucial.

What are the recommended installation and maintenance practices for PVC ventilation ducting fabric to ensure optimal performance and longevity?

Installation Practices:

Proper Planning and Design: Before installation, carefully plan and design the ducting system, considering factors such as airflow requirements, pressure handling capabilities, and space constraints. Ensure that the system layout is optimized for efficient airflow and minimal resistance.

Correct Sizing and Support: Properly size the PVC ventilation ducting fabric to match the required airflow capacity. Oversized or undersized ducting can lead to inefficient performance. Additionally, provide adequate support for the ducting to prevent sagging or stress on the fabric. Use suitable hangers, brackets, or supports at regular intervals to maintain the desired shape and alignment.

Seal Joints and Connections: During installation, ensure that joints and connections between PVC fabric sections are properly sealed to prevent air leaks. Use compatible adhesive tapes or sealants specifically designed for PVC ducting fabric. Airtight connections help maintain the desired airflow and prevent energy loss.

Avoid Sharp Bends and Obstructions: Minimize the number of sharp bends in the ducting system, as they can cause increased resistance and airflow disruption. Ensure that the fabric is not bent beyond its recommended bending radius. Avoid placing obstructions or objects that could impede the airflow within or near the ducting system.

Consider Thermal Expansion: PVC fabric expands and contracts with temperature changes. Allow for thermal expansion by incorporating expansion joints or providing sufficient slack in the fabric during installation. This prevents excessive stress on the fabric, ensuring its longevity.

Maintenance Practices:

Regular Inspection: Perform routine inspections of the PVC ventilation ducting fabric to check for any signs of damage, wear, or corrosion. Look for tears, abrasions, loose connections, or leaks. Promptly address any issues to prevent further damage and ensure efficient operation.

Cleaning: Regularly clean the PVC fabric to remove dust, debris, or contaminants that can accumulate over time. Use non-abrasive cleaning methods such as wiping with a soft cloth or vacuuming. Avoid using harsh chemicals or abrasive materials that may damage the fabric.

Address Mold or Mildew Growth: If mold or mildew is detected on the PVC fabric, take immediate action to address the issue. Clean the affected area using mild detergent and water solution, following manufacturer guidelines. Ensure that the fabric is thoroughly dried to prevent further mold growth.

Repair and Replacement: If any damage or deterioration is identified during inspections, promptly repair or replace the affected sections. Use compatible repair materials and follow manufacturer instructions. Timely repairs help maintain the performance and integrity of the ducting system.

Preventive Maintenance: Implement a preventive maintenance program that includes regular inspections, cleaning, and maintenance tasks. Follow the manufacturer's recommendations for specific maintenance intervals and procedures. This proactive approach can identify potential issues early on and extend the lifespan of the PVC ventilation ducting fabric.

Document Maintenance Records: Maintain detailed records of installation, maintenance, repairs, and replacements performed on the PVC fabric. This documentation helps track the history of the system, ensures consistency in maintenance practices, and provides valuable information for future reference or audits.

English

English 中文简体

中文简体 Español

Español