For the outdoor temporary exhibition and advertising industry, the stability and durability of inflatable billboards and inflatable displays are crucial, especially in harsh weather conditions. The sealing performance of PVC Inflatable Fabric (polyvinyl chloride inflatable fabric) is a key factor to ensure that these inflatable products remain stable in severe weather such as wind and rain and avoid air leakage. Here are a few key points on how PVC Inflatable Fabric guarantees its sealing performance:

HIGH QUALITY MATERIAL: PVC Inflatable Fabric is made of high quality polyvinyl chloride material, which has excellent durability and waterproof properties. The material itself has good stretch resistance and wear resistance, and can maintain the stability of its structure and performance over long periods of use.

Precision manufacturing process: During the manufacturing process, PVC Inflatable Fabric requires precise stitching and processing to ensure that the connection between each part is tight and gap-free. Sewing process is one of the key links, using high-quality sewing thread and professional sewing technology to ensure that the seams are strong and not easy to break. In addition, heat sealing technology or high-frequency welding technology may also be used to enhance the sealing performance of the connection.

Sealants and sealing strips: Sealants or sealing strips may be used in key parts of inflatable products, such as air valves, seams and interfaces to further enhance the sealing effect. These sealing materials can effectively prevent gas from escaping from tiny gaps and improve the sealing performance of inflatable products.

Strict quality control: During the production process, manufacturers will conduct strict quality control on PVC Inflatable Fabric to ensure that it meets relevant standards and requirements. This includes testing of material quality, monitoring of manufacturing processes, and performance testing of finished products. These measures help ensure that PVC Inflatable Fabric has excellent sealing performance and other required properties.

Maintenance and care: Although PVC Inflatable Fabric itself has excellent durability and sealing properties, it still requires proper care and maintenance during use. Regular inspection and repair of any potential damage or wear, and keeping inflatables clean and dry will help extend their service life and maintain good sealing properties.

PVC Inflatable Fabric ensures its good sealing performance through high-quality materials, precise manufacturing processes, the use of sealants and sealing strips, strict quality control, and proper maintenance and upkeep. This allows inflatable billboards and inflatable displays to remain stable in bad weather and avoid air leakage, providing a reliable solution for the outdoor temporary exhibition and advertising industry.

拷贝.jpg?imageView2/2/format/jp2)

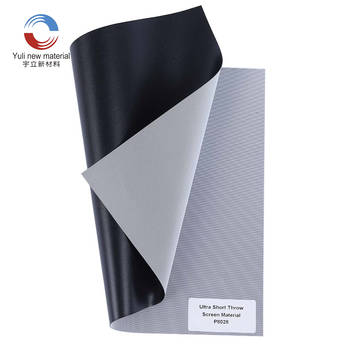

510G 840D 18X18 INFLATABLE CASTLE FABRIC

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)

拷贝.jpg?imageView2/2/w/346/format/jp2/q/70)

拷贝.jpg?imageView2/2/w/346/format/jp2/q/70)

拷贝.jpg?imageView2/2/w/346/format/jp2/q/70)

拷贝.jpg?imageView2/2/w/346/format/jp2/q/70)